Special Activities

Nativel processes sensitive products in a controlled environment. End products can thus be protected particularly well from contamination.

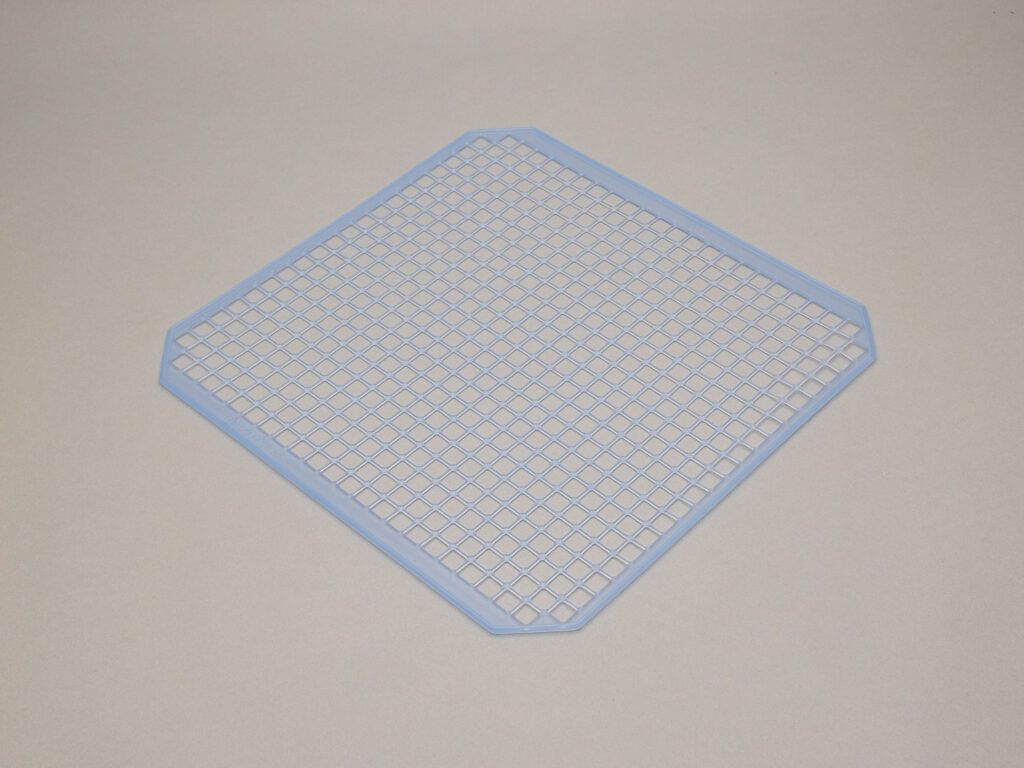

Rework of Silicone Parts

Nativel carries out rework of plastic parts. This includes particularly sensitive products. Extensive training combined with many years of experience ensure that demanding customer requirements are met. The production focus lies on products for the medical technology sector. These include, for example, ventilation masks for neonates and infants, components for surgical equipment or accessories for autoclaves.

100% Control of Silicone Parts

Some products are subject to 100% manual control due to their respective application. This activity requires the utmost patience and concentration. It is carried out by proven employees with many years of experience. For example, Nativel checks tubes for dialysis units.

Post-Curing of Silicone Parts

In order to meet high physical requirements, especially in the field of medical and food technology, silicone parts are often post-cured. For this purpose, Nativel uses tempering ovens equipped with a secured monitoring and documentation system.

Meeting Your Quality Needs

Nativel performs batch tracking for the activities described. Upon customer request, the specifications of the ISO 9001 can be exceeded significantly. Some end customers have special requirements due to their ISO 13485 certification. In addition, Nativel also processes FDA-registered products.